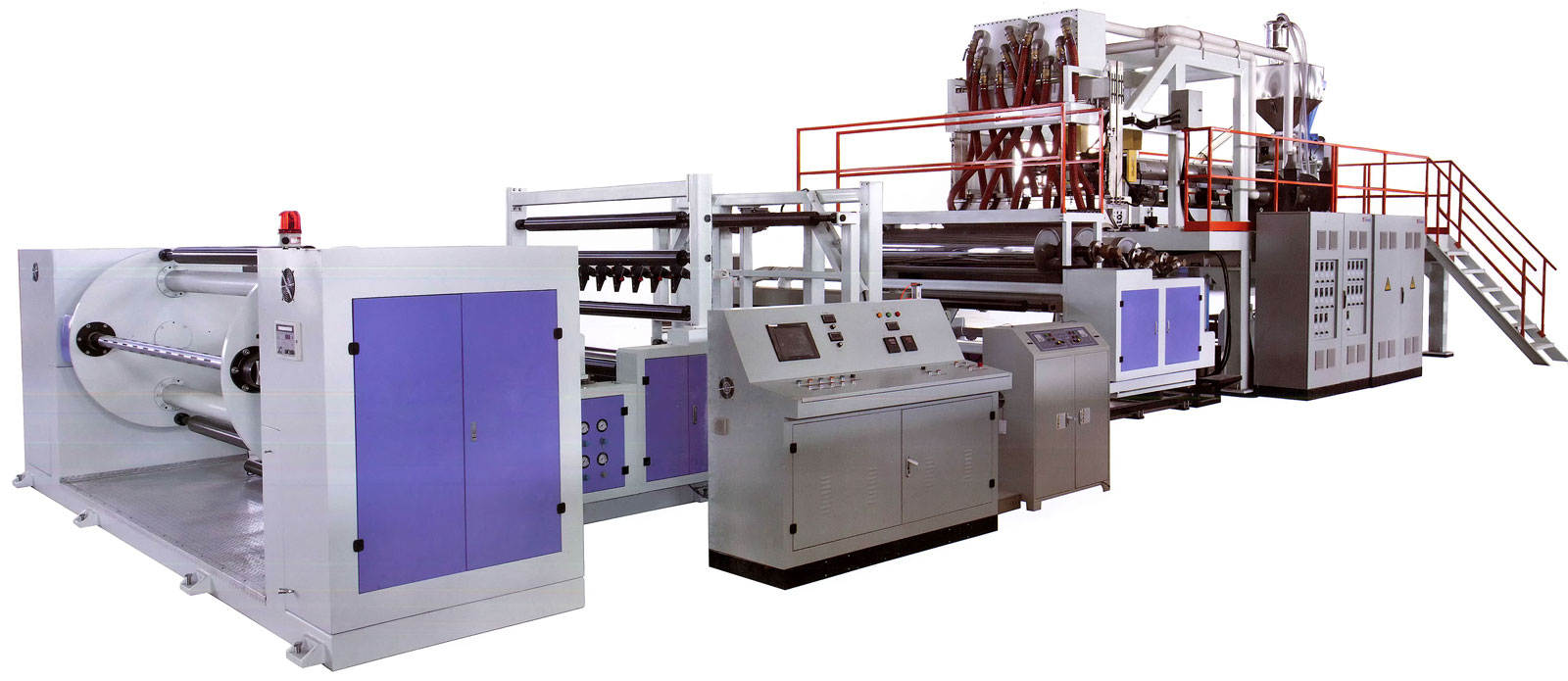

Cast / Embossed Film Line

Introduction

The cast film line produces flat or embossed films for hygiene, medical and packaging applications. The most optimized design of extruder and T die guarantees high-performance extrusion and various levels of features and automation are available to best meet your needs.

The line uses extruder to convert polymers into continuous melt resin which are formed by T die into film structure. Through such a cast film extrusion system, an engraved steel roll and silicon rubber roll are installed at the casting unit of the line. When the melt resin comes out of the T die, it is pressed onto the embossing roll by silicon roll to produce embossed film.

Application

The cast embossed process has a wide range of applications, such as PE film for baby diaper, sanitary napkin, inconvenience products, pet pad, disposable bedsheet, medical dressings, grown, gloves, shoes cover, rubber release film, table cloth, shower curtain, and so forth.

Features & Advantages

- Any film width (up to 4000mm) at customer's disposable.

- Easy to change embossing roll for various emboss patterns.

- Very low variation of film thickness

- In-line film edge trim and recycling

- In-line extrusion coating is optional

- Auto film winder with different size of air shaft

Overview

Sample Products

Technical Data

| Model No. | Screw Diameter | Die Width | Film Width | Film Thickness | Line Speed |

|---|---|---|---|---|---|

| F120-1600 | ø120mm | 1900mm | 1600mm | 0.02-0.15mm | 180m/min |

| F125-2000 | ø125mm | 2300mm | 2000mm | ||

| F135-2500 | ø135mm | 2800mm | 2500mm |