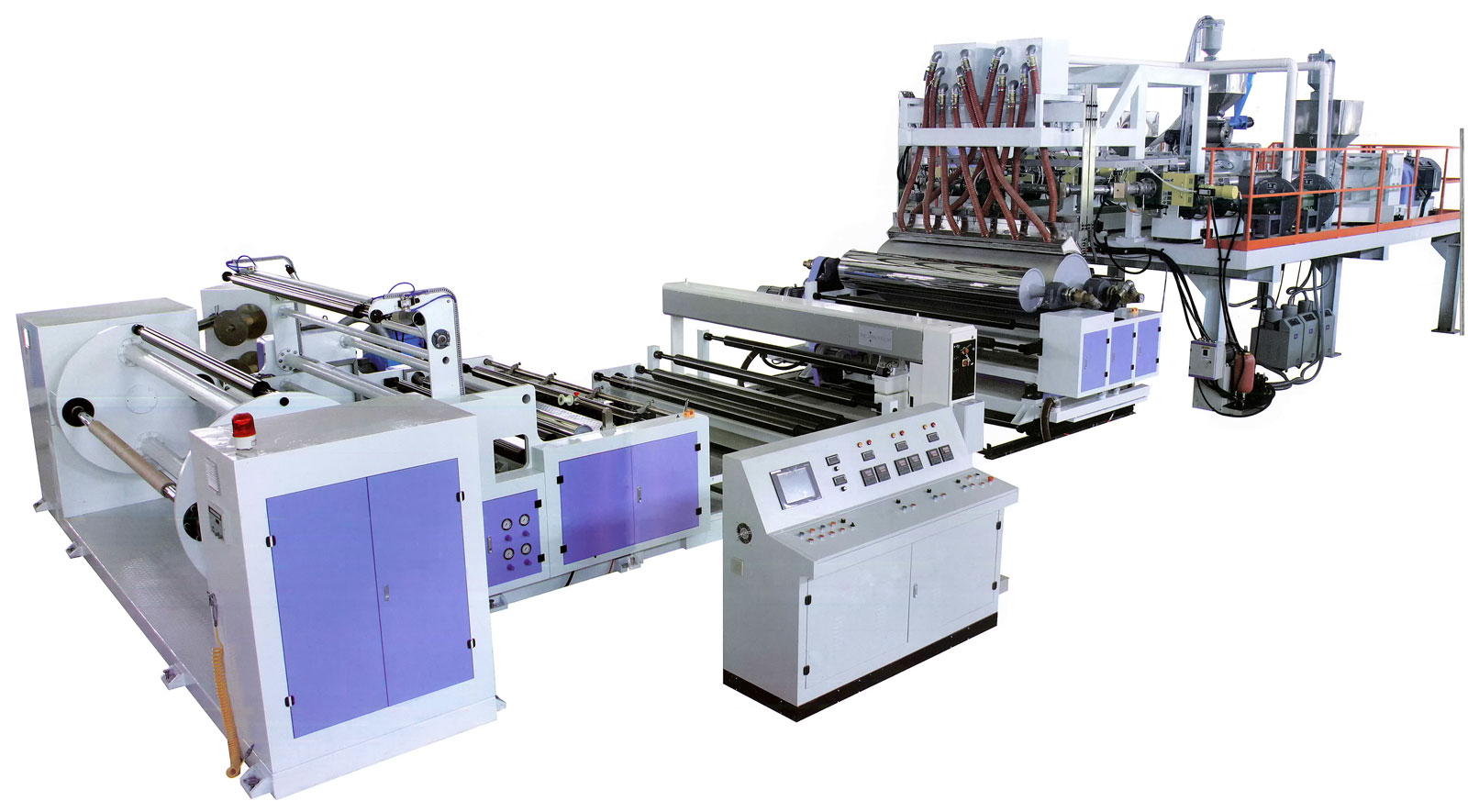

Multilayer Cast Film Line

Introduction:

Our multi-layer cast film line use co-extrusion to optimize film performance for hygiene, medical and packaging application. The lines offer many options, such as 2-layer, 3-layer, and 5-layer film coextruded structure. The number of coextrusion layers depends on the market need.

Varying from reducing resin cost to improving film properties and appearance, the advantages of coextrusion are versatile: to improve film tensile force; to improve heat sealability and printability; to reduce resin cost by using the recycled or re-processed in an inner film layer; to produce two-color film using different color resins.

Application

The multi-layer coextrusion process is used to produce hygiene films, CPP film, stretch film, cling film, masking film, agricultural films, medical films, barrier films for packaging food such as meats, snack, bakery, frozen foods, and so forth.

Features & Advantages

- Any film width (up to 4000mm) at customer's option

- Very low variation of film thickness

- In-line film edge trim and recycling

- In-line extrusion coating is optional

- Auto film winder with difference size of air shaft

Overview

Technical Data

| Model No. | Screw Diameter | Die Width | Film Width | Film Thickness | Line Speed |

|---|---|---|---|---|---|

| F65/110/65-1500 | ø65 mm / ø110 mm/ ø65 mm | 1800 mm | 1500 mm | 0.02-0.150 mm | 180 m/min |

| F65/120/65-2000 | ø65 mm / ø120 mm/ ø65 mm | 2300 mm | 2000 mm | ||

| F90/150/90-3000 | ø90 mm / ø150 mm/ ø90 mm | 3300 mm | 3000 mm |