Disposable Surgical Mask Automatic Production Line

Face Mask Production Line Application

The production line is designed to produce 3 layers Surgical Mask. The surgical mask is the most commonly worn cheap and disposable masks, will limit the chance of inhaling large, infectious particals circulating near the face.

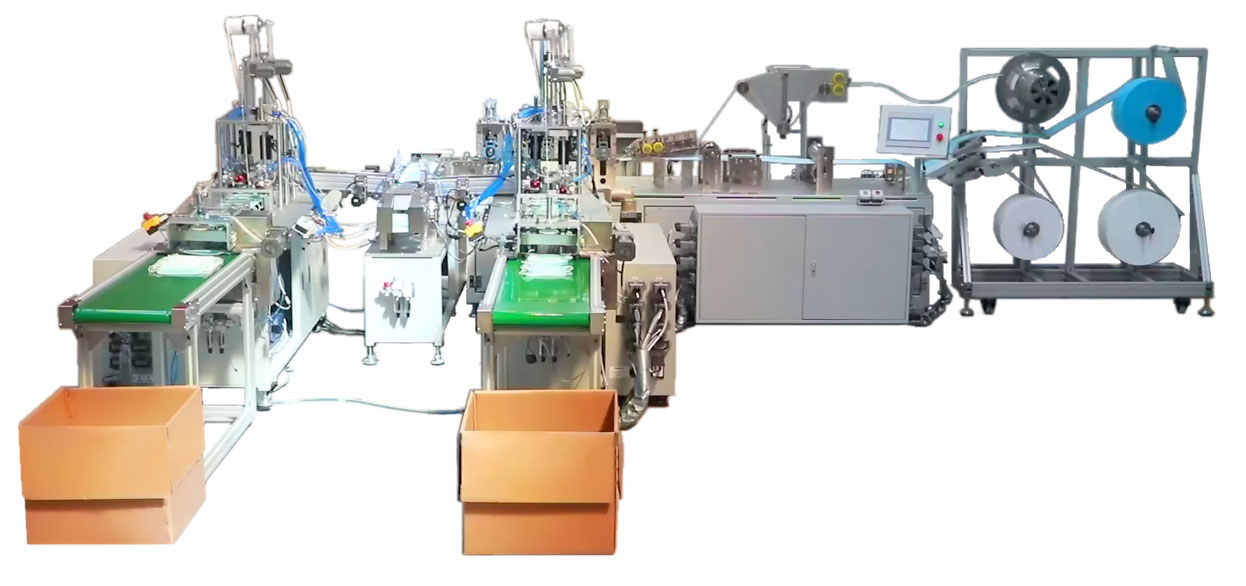

Overview

surgical mask production line overview

Features & Advantages

Automatic Production Line for Disposable Surgical Mask has a number of features and advantages:

- Production adopted the 1-to-2 design, one set of mask making station connects two sets of earloop welding station.

- Auto-align 3 material rolls to be feed in machine, the Outer, Filter and Middle layers.

- Automatically fold and make mask pleats, which offer more room when wearing.

- Continuously welding the both side of three layers of material together by ultrasonic welding rollers, then cut into mask pieces.

- Nose-bridge can be integrated into mask with auto feeding, cutting and ultrasonic welding.

- Distribute the mask panels to welding stations separately, with two earloop welding stations working at full speed to reach the higher productivity.

- Cut Earloop strip and fix to mask by ultrasonic welding automatically.

- Collect finished masks from the conveyors

- Stack up finished mask on conveyor as per the designed number then send into Packing machine to pack masks automatically [Optional].

- Additional device for one more layer fabric (total 4 layers) [Optional device]

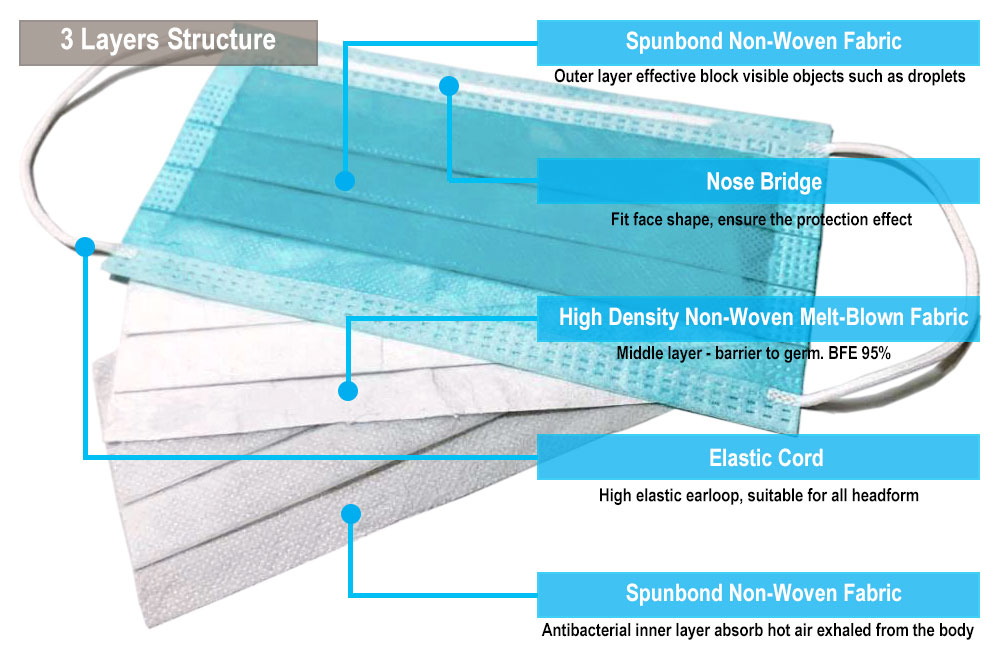

Product Sample

Disposable Face Mask Production Line Technical Specification

| Parameter | Value | |

|---|---|---|

| Mask Type | Disposable Medical Mask, General Surgical Mask | |

| Mask Size | Standard Adult Size: 175 mm × 95mm / Children Size Optional: 165mm × 95mm, 145mm × 95 mm | |

| Line Speed | 100 pcs/min | |

| Mask Material | Spunbond nonwoven, Melt-blown fabric | |

| Layer Quantity | 3 Layers | |

| Processing Mode | Ultrasonic Welding | |

| Operation Screen | 10 inches touch screen | |

| Air Source | 0.4≤ P ≤0.7 MPa, flow rate 300 L/min | |

| Ultrasonic Generator | 220V, 20kHz, 1.5 kW | |

| Power consumption | 20 kW | |

| Voltage | single-phase 220V/50/60Hz or three-phase 380V/50/60Hz | |

| Required Space | 5000 mm × 7000 mm × 1800 mm | |

| Weight | ≤2000kg | |

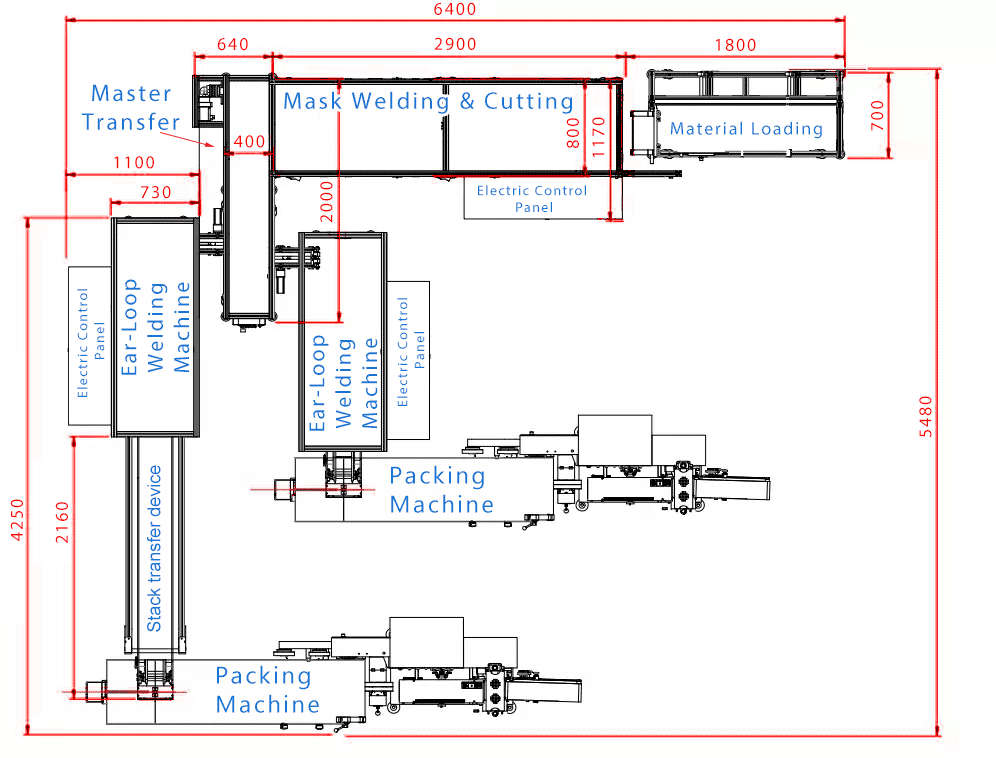

| Installation Area | 6400 × 5480 mm | |

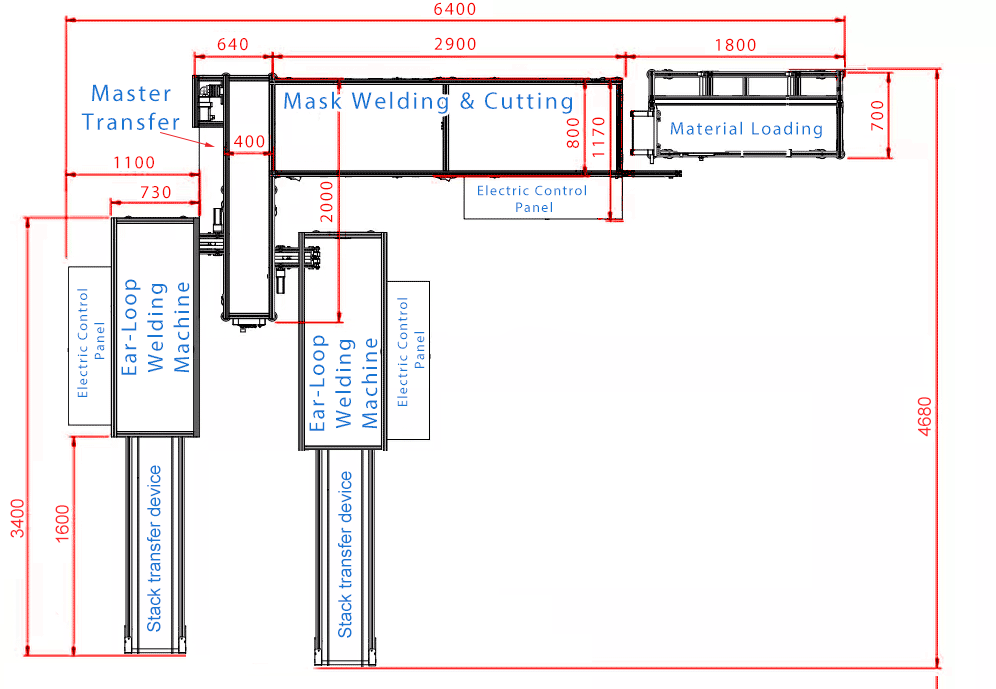

| Component | Inner package size | Quantity |

| Mask blank machine: | 2900 mm × 1170 mm × 1600 mm | 1 set |

| Automatic conveyor system | 2000 mm × 640 mm × 1200 mm | 1 set |

| Ear loop welding station | 2000 mm × 1000 mm × 1750 mm (single set) | 2 set |

| Material loading stand | 1600 mm × 700 mm × 1660 mm | 1 set |

| Stack transfer device | 160 0mm × 500 mm × 850 mm | 1 set / 2 set |

Layout of Automatic Face Mask Production Line (no packaging function)

Layout of Automatic Face Mask Production Line with packaging function

3 layers disposable surgical mask structure

The disposable surgical mask automatic production line is for produce 3 layers surgical mask, here is the mask structure.