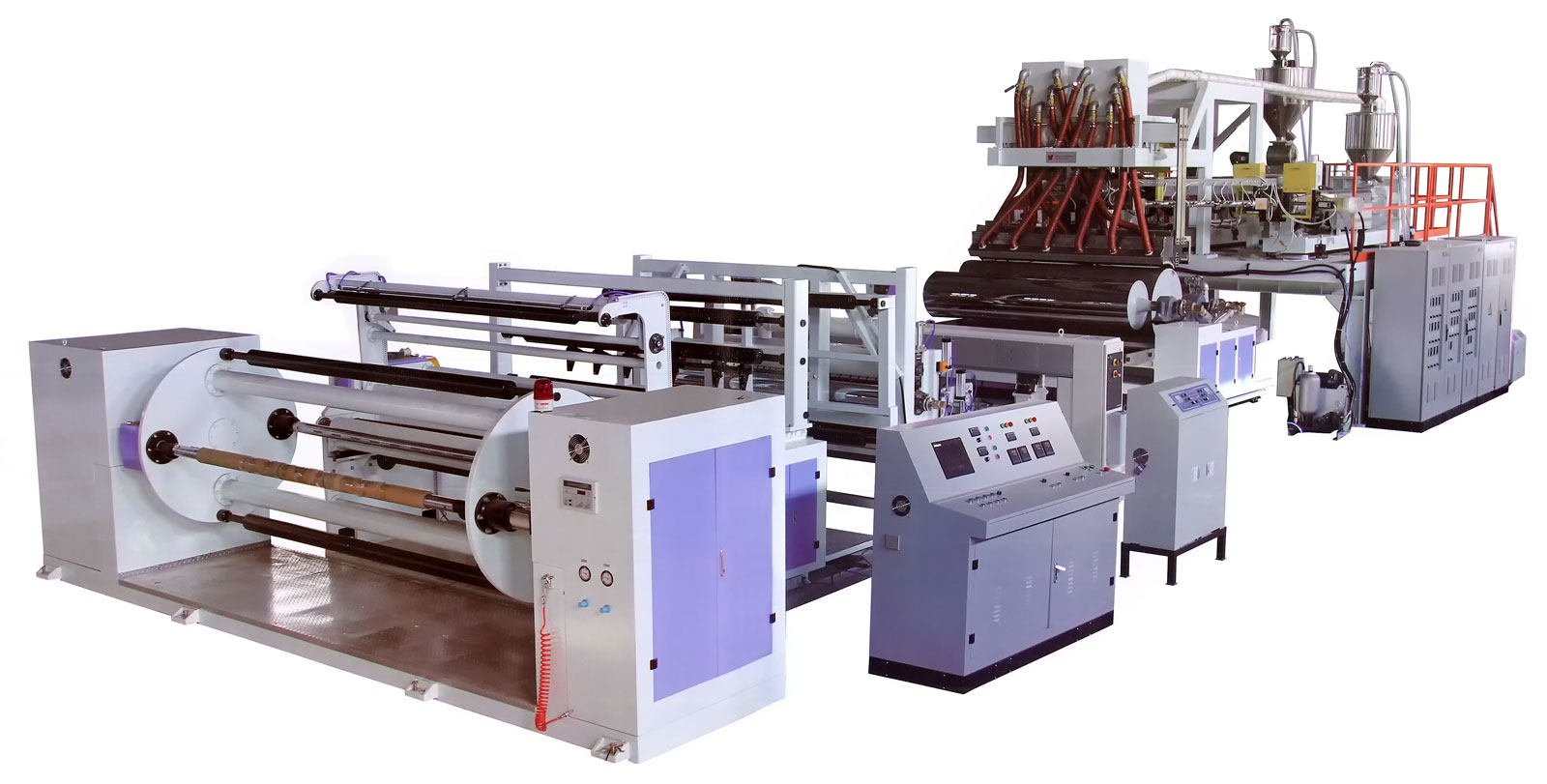

CPP Cast Film Line

Introduction:

The CPP cast film line is used to produce high-quality cast polypropylene film (CPP film) for a wide range of packaging applications. Equipped with auto thickness controlling system and efficient chill roll, the line produces CPP film of high transparency and very low gauge variation, ideal for laminating and metalizing. The 3-layer CPP film is most welcome in the market.

Application

Wide packaging application for processed food and bakery products, cosmetics, pharmaceutical, bakery, confectionery, stationery, apparel, DVD case and flower; lamination grade CPP film used as a heat seal layer along with BOPP or polyester film in a laminate for packing the articles; metalized grade CPP film with co-polymer and homo-polymer to meet the specialized needs for the packaging of various products.

Features & Advantages

- Options for up to 5-layers coextruded film structure

- Option for up to 4000mm film wide

- Air knife and high performance chill roller

- Automatic film thickness controlling

- In-line edge trim and recycling

- Auto film winding

Overview

Technical Data

| Model No. | Screw Diameter | Die Width | Film Width | Film Thickness | Line Speed |

|---|---|---|---|---|---|

| FC65/110/65-1600 | ø65 mm / ø110 mm/ ø65 mm | 2000 mm | 1600 mm | 0.02-0.150 mm | 250 m/min |

| FC65/125/65-2000 | ø65 mm / ø125 mm/ ø65 mm | 2400 mm | 2000 mm | ||

| FC90/135/90-2500 | ø90 mm / ø135 mm/ ø90 mm | 2900 mm | 2500 mm |