Automatic FFP2 Duckbill Respirator Production Line

Duckbill Mask Production Line Application

Fully automatic FFP2 Duckbill Respirator Production Line is designed for processing Duck Bill Respirators by ultrasonic welding, from feeding raw nonwoven materials and nose wire, folding to welding ear-loop. The respirators could meet the FFP1~FFP3 and N95~N99 levels of filtering efficiency of airborne particles.

These medical masks are ideal for pandemic preparedness.

FFP2 Duckbill Respirator defenses against influenza, reduces wearer exposure to the spray, aerosol of blood and body fluids or non-oil-based particles in a wide range of industrial or clean-room applications and potential contamination. At least 95% filtration efficiency against solid and liquid aerosols that do not contain oil. Low breathing resistance and long lifetime for use.

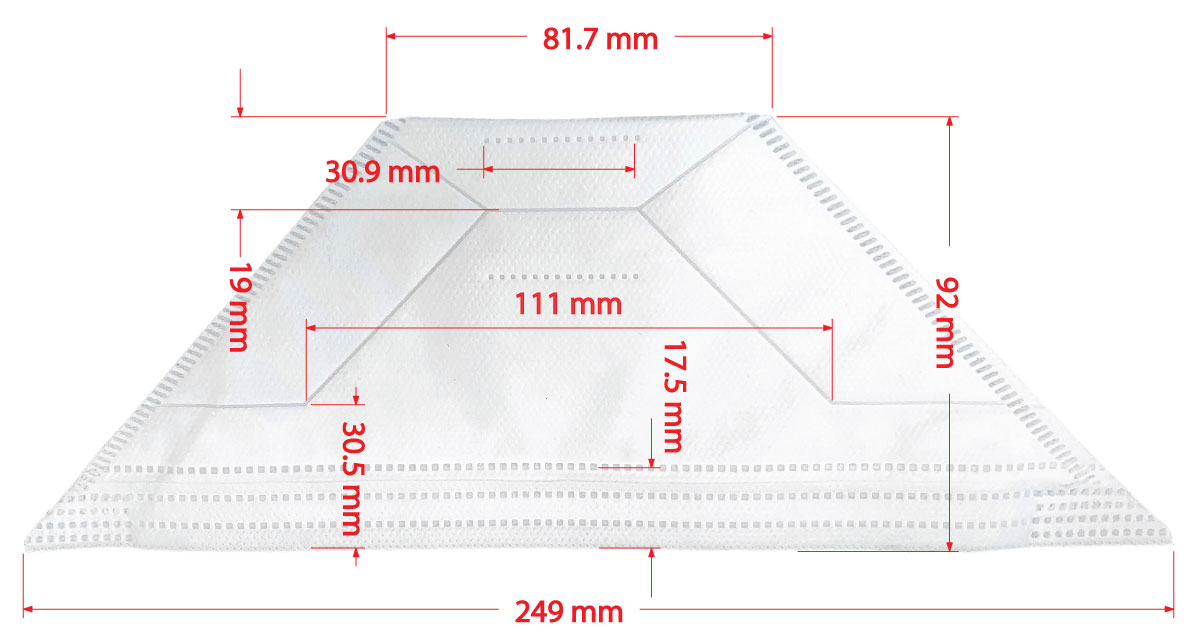

Duckbill Mask Dimensions

N95 Duckbill type mask has foldable design for easy carry and storage. This unique design of the shape with adjustable nose wire fits different facial shape with minimum leakage.

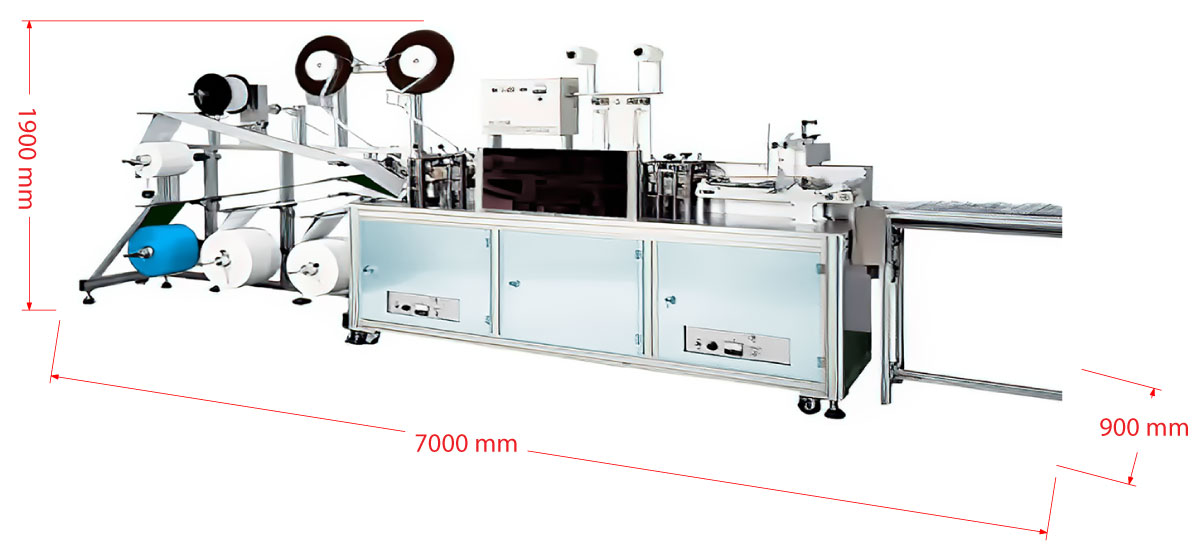

Duckbill Mask Production Line Overview

Features & Advantages

Automatic Duckbill Mask Production Line has a number of features and advantages:

- machine compact;

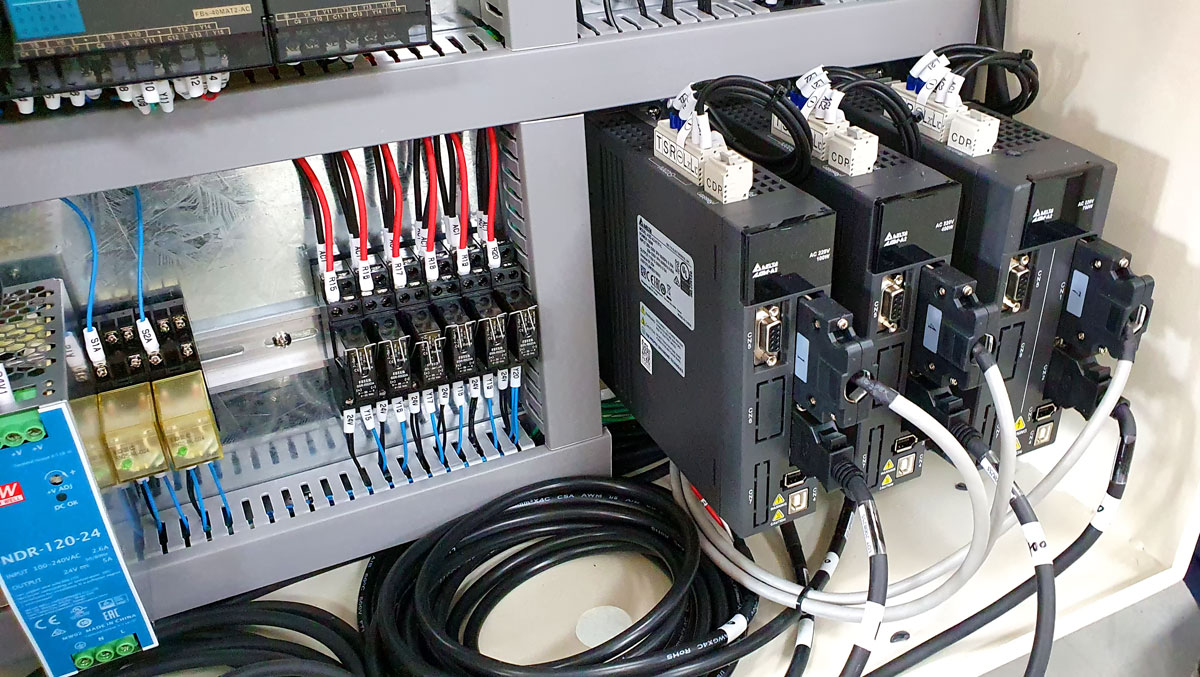

- PLC control.

- all aluminum alloys made construction;

- special loop application and hole cutting for exhalation valve is optional;

- with nose wire, elastic band inside mask;

- use Taiwan made powerful ultrasonic welding systems;

- fully automated mask making machine, just 1 line 1 operator being able to make product.

Technical Data of the Masks Production Line

| Parameter | Value |

|---|---|

| Mask Type | Duckbill Type |

| Mask Size | 249 mm × 92 mm × (size can be customized) |

| Line Speed | 40‐60 pcs/min (depends on the material thickness) |

| Operator | 1 |

| Ultrasonic Generator | Taiwan made |

| Power consumption | 8.0 kW |

| Voltage | three-phase 220V/50Hz |

| Machine Size | 7000(L) × 900(W) × 1900(H) mm |