Nonwoven Materials for Medicine, Hygiene and PPE

Breathable double-layer laminated non-woven fabric for medicine, hygiene and PPE

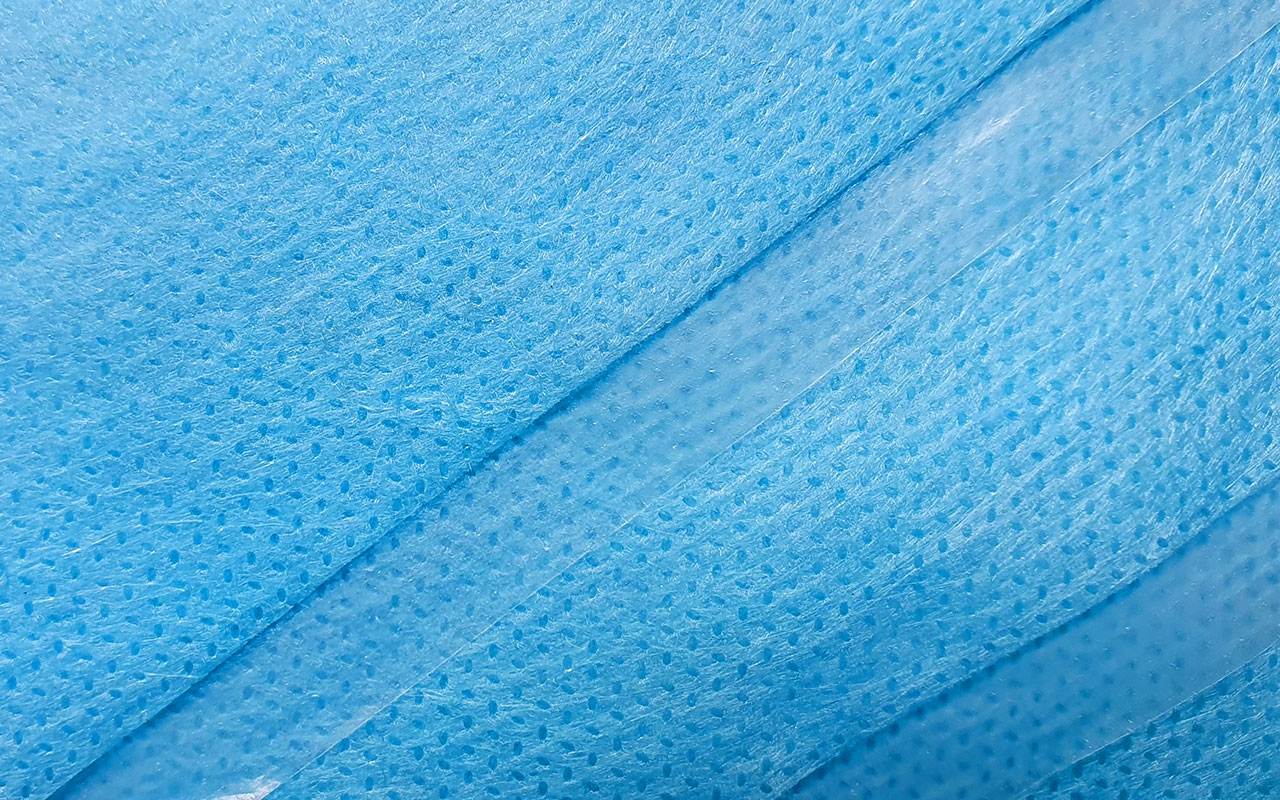

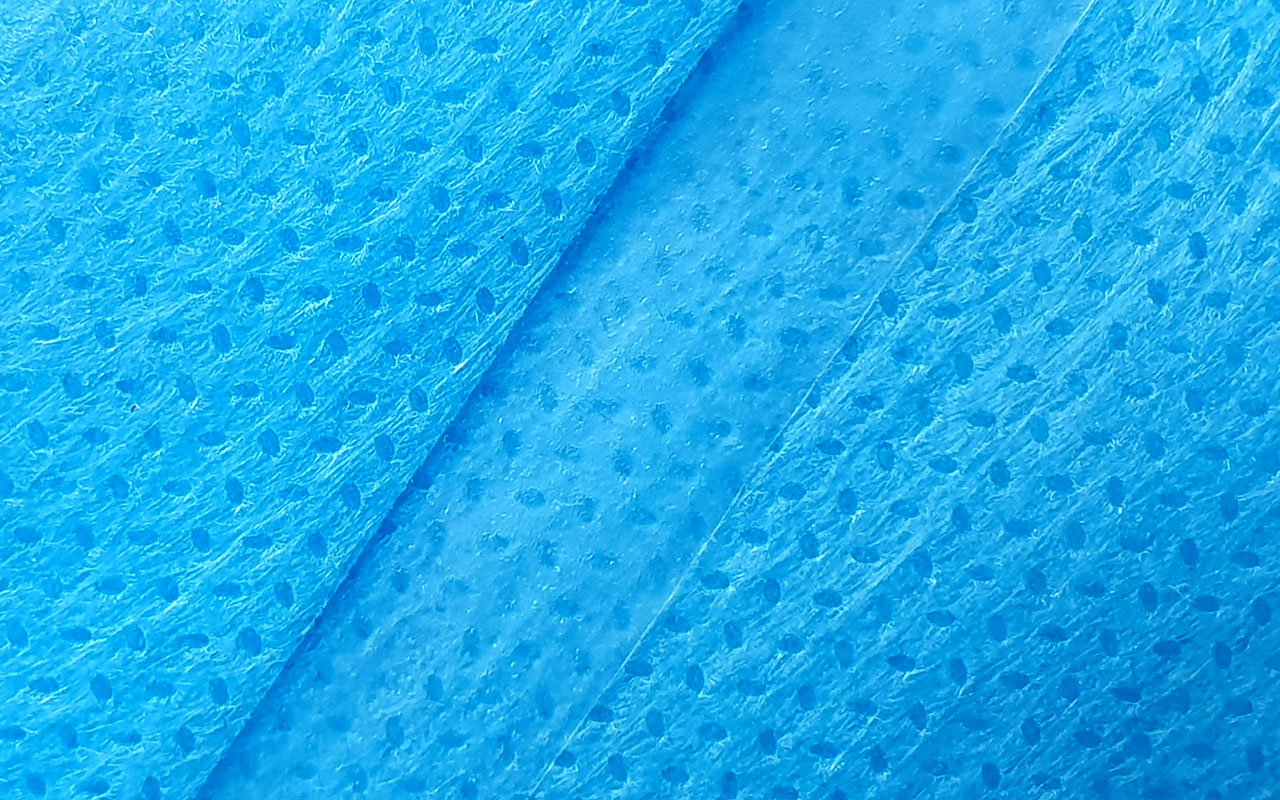

This 2-layer non-woven breathable material consisting of a thermally bonded non-woven fabric and a breathable polyethylene film bonded with adhesive.

Applications for laminated nonwoven thermobonded fabric

Breathable laminated materials are widely used in the hygiene industry as an outer layer of baby and adult diapers, women's hygiene products, diapers. Modern technology allows to create a protective layer that retains moisture inside the diaper, while allowing the skin to breathe.

Non-Woven Hydrobonded Fabric Features

- Air permeability.

- Watertight (leak-proof).

- Bonding with odorless glue.

- Ability to apply 4-color painting by flex printing method.

- Softness for a pleasant tactile sensation.

- Surface density 25-90 gsm

- Fabric width 1500 mm

Nonwoven Material Technical Data Sheet

| Description | Method | Physico-mechanical indexes for the material with surface density, g/m2 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 15-19 | 20-24 | 25-34 | 35-39 | 40-49 | 50-59 | 60-80 | 81-99 | 100-114 | 115-150 | ||

| 1. Variation coefficient of surface density, %, no more | EN ISO 9073.1 | 4,0 | |||||||||

| 2. Breaking load, N, no less: MD | EN ISO 9073.3 | 32 | 44 | 51 | 70 | 100 | 120 | 135 | 160 | 170 | 180 |

| Breaking load, N, no less: CD | 17 | 24 | 28 | 40 | 60 | 70 | 90 | 100 | 110 | 120 | |

| 3. Elongation at break %, no more MD CD | EN ISO 9073.3 | 35-105 | 35-105 | 35-105 | 60-150 | 60-150 | 60-150 | 60-150 | 60-170 | 60-170 | 60-170 |

| 40-105 | 40-105 | 40-105 | 60-150 | 60-150 | 60-150 | 60-150 | 70-190 | 70-190 | 55-190 | ||

| 4. Steadiness to UV irradiation, %, no less after 500 hours (for UV stabilized materials) | ASTM D4355 | 45 | |||||||||

| 5. Tear resistance, N/10cm, not less (for C marked materials) MD CD | EN 12310-1 | 15 | 20 | 25 | 35 | 40 | 60 | 70 | 90 | 100 | 110 |

| 15 | 20 | 25 | 35 | 40 | 60 | 70 | 90 | 110 | 112 | ||

| 6. Variation coefficient of breaking load, % | EN ISO 9073.1 | 15 | 15 | 15 | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

Permissible deviations from norms of width should not exceed ±3mm (200-300 mm), ±6mm (301-700 mm), ±10mm (701-1000mm), ±15mm (1001- 2000mm), ±20mm (2001-3200mm).

Items 5 and 6 under control on consumer's request.

It is allowed according to agreement with consumer to change physico-mechanical properties of material.

Combined Non-Woven Fabric Structure

| Layer | Material | |||

|---|---|---|---|---|

| outer | spunbond | |||

| inner | polyethylene film |

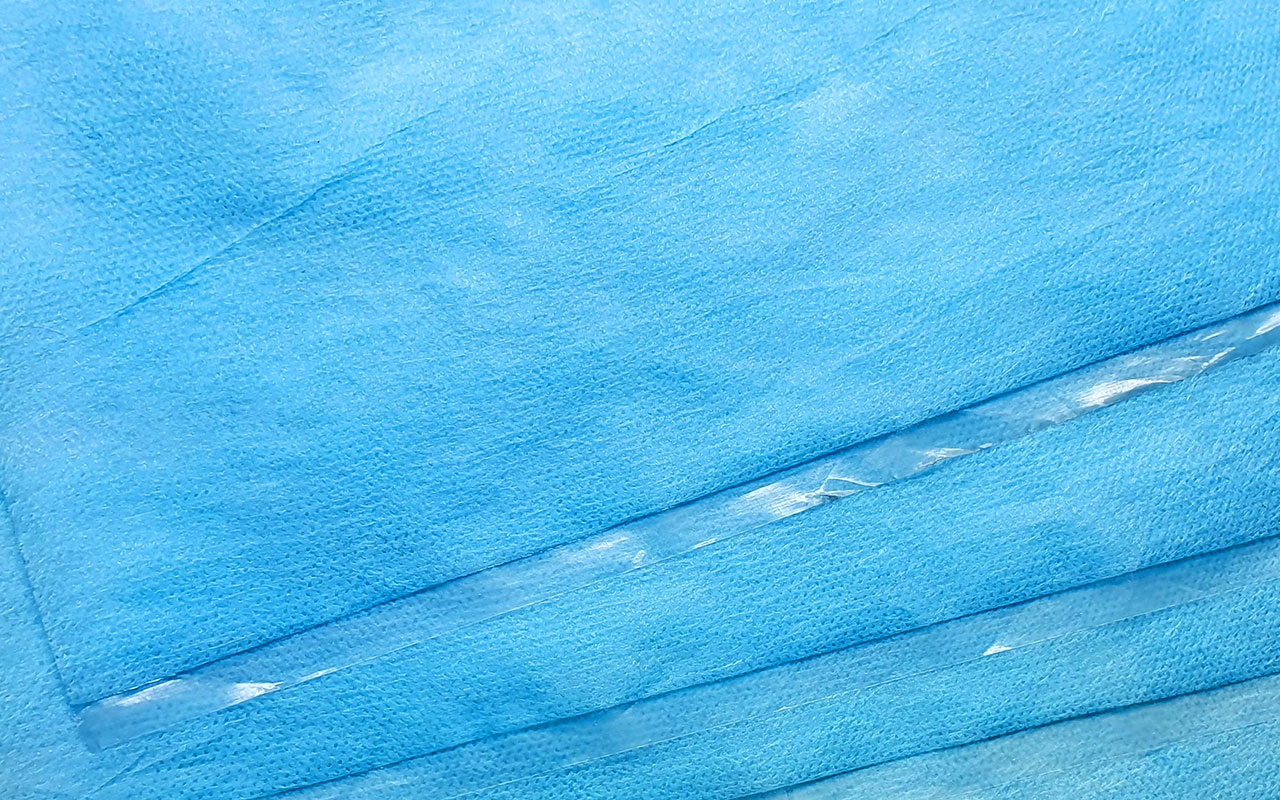

Laminated Non-Woven Material Photo