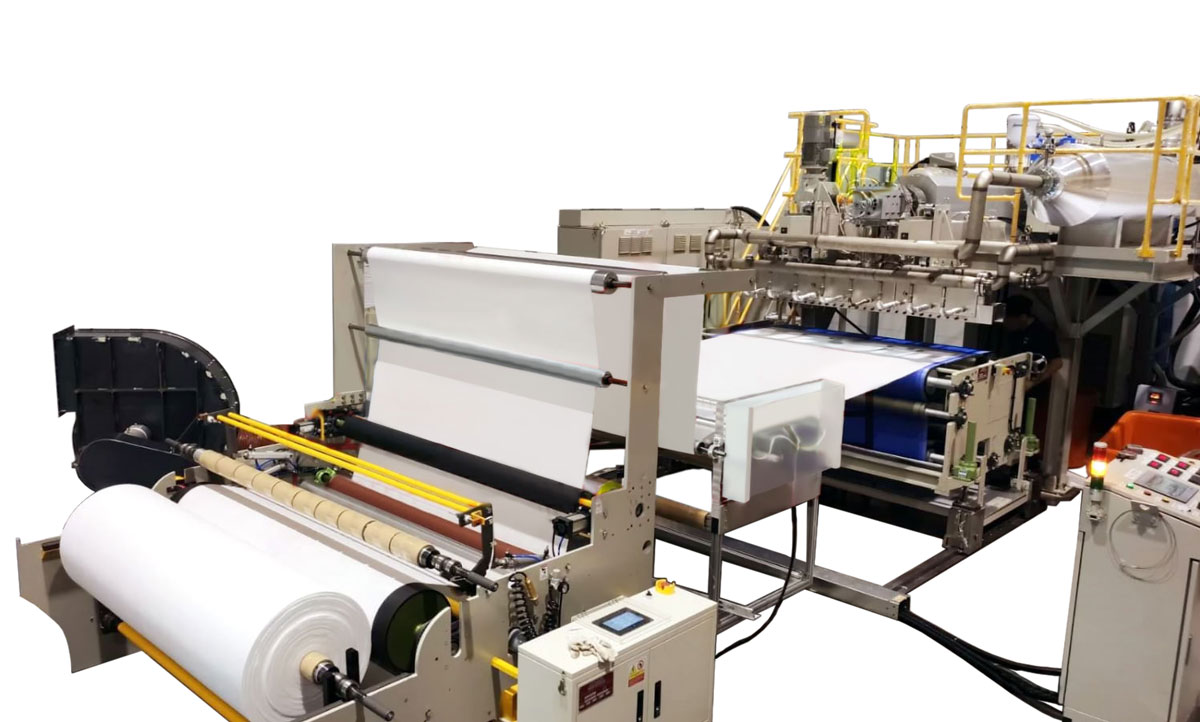

PP Meltblown non-woven fabric extrusion line 1600mm

Meltblown Extrusion Line Overview

Extrusion Line Specification

| Parameter | Value |

|---|---|

| Raw material to be used | PP (Polypropylene) |

| Width of finished product | 1600 mm |

| Max. extruding output: | 2000 kg / daily |

| Machine linear velocity: | Mechanical design 40 m/min |

| Voltage* | 220V / 380V / 415V 3-Phase 50Hz / 60Hz |

The power line and ground line should installed seperately.

Equipment Summary

| Line Components | Quantity |

|---|---|

| Feeding System | 1 set |

| Extruder Ø75mm | 1 set |

| Screen Changer | 1 set |

| Gear Pump | 1 set |

| Meltblown T-Die | 1 set |

| Cooling Apparatus | 1 set |

| Electret System | 1 set |

| Slitting Unit | 1 set |

| Winder | 1 set |

| Electricity Control System | 1 set |

Equipment Detail

Feeding System

- 100 kg hot air hopper.

- Hopper loader × 1 set.

- Adapter × 1 set.

- Masterbatch doser × 2 sets.

Extruder Ø75 mm

Motor

- 55kW high efficiency AC motor.

Gear Box

- High precision, noiseless gearbox.

- Drive gear shaft made of carbon steel with surface hardness HRC60-650.

Screw

- Ø75mm screw diameter made of SCM 440 alloy.

- Screw surface hardness HRC 580±1.

- Screw external surface is chrome plated and polished.

- Screw LID ratio 32:1.

Barrel

- Ø75mm barrel made of SACM 645 material.

- Barrel surface hardness HRC 65-680.

- Barrel internal surface is ground and polished.

- PID temperature control.

Screen Changer

- With thermal sensor.

- Made with heat resistant alloy and processed by tempering treatment.

- Pressure transmission and digital pressure display.

- Pressure over-load protecting system.

Gear Pump

- With heat melting temperature and pressure sensor.

- Made of Alloy steel.

- Pump supporter and piping × 1 set.

- Flanges connection × 2 pcs.

- PID temperature control.

Meltblown T-Die

- Material: mold steel.

- Burnish inside the Die, by a two mirror process technology.

- Hot air heater.

Cooling Apparatus

- Conveyor belt with antiadhesion treatment.

- Attraction system.

- High performance motor.

- Reducer.

Electret System

- High voltage discharge electrode × 2 sets.

- Metal roller.

- Electricity control system.

Slitting Unit

- Circular cutter.

- 3″ air shaft.

- Manual control for change.

- Winder for edge-trimming.

Winder

- Type: surface winding.

- Maximum winding diameter: Ø600 mm.

- 3″ air shaft × 2 pcs.

- Driving motor with reducer × 1 set.

- Automatic cutting.

Electricity Control System

- PLC + Human-machine interface control system.