Nonwoven Materials for Medicine, Hygiene and PPE

Non-Woven Thermobonded Fabric for Medicine and Protective Clothing

This nonwoven material is made on technology REICOFIL®4. At first polypropylene threads are formed by extrusion, then aerodynamic formation of canvas is made and then thermal fastening on calender is made.

Applications for nonwoven thermobonded fabric

This nonwoven thermobonded material is widely used in light manufacturing for sewing medical and special protective clothing, various items of sanitary purposes.

Non-Woven Hydrobonded Fabric Advantages

- easy sterilization at 100-130°C;

- the ability to do laundry with antistatic added;

- easy ironing at low temperatures;

- non-toxic;

- does not cause allergic reactions;

- dustproofing properties;

- acid resistance (except particularly concentrated nitric, chlorosulfate and other acids);

- lightweight

- antistatic, hydrophobic, hydrophilic, fire extinguishing are possible;

- possibility of laminating with polypropylene;

- wide range of colours;

- cost effectiveness in manufacturing.

Non-Woven Fabric Technical Specification

| Parameter | Value |

|---|---|

| Surface density | 25 - 60 gsm |

| Fabric width | 180 - 4200 mm |

| Breaking load in longitudinal direction | 30 - 80 N |

| Breaking load incross-sectional direction | 20 - 60 N |

| Elongation of break in longitudinal direction | 150 - 160 % |

| Elongation of break in cross-sectional direction | 150 % |

| Time of liquid passing | 7 second |

| Air permeability | 880 - 1400 dm3/m2 per second |

| Harshness in longitudinal direction | 0,006 - 0,009 N |

| Harshness in cross-sectional direction | 0,008 - 0,011 N |

| Dustpenetration | 1790 - 2150 mg/m2 |

| Hygroscopic property | 0,9 - 1,2 % |

| Stability to abrasion | 107 - 121 cycles |

| Surface electrical resistance | 109 - 1010 Om/sm2 |

Nonwoven Material Technical Data Sheet

| Description | Method | Physico-mechanical indexes for the material with surface density, g/m2 | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 10-12 | 13-15 | 16-20 | 21-30 | 31-40 | 41-50 | 51-60 | 61-80 | 81-100 | 101-120 | 121-130 | 131-150 | ||

| 1. Variation coefficient of surface density, %, no more | EN ISO 9073.1 | 4,5 | 4,0 | ||||||||||

| 2. Breaking load, N, no less: MD | EN ISO 9073.3 | 19 | 25 | 30 | 44 | 58 | 78 | 95 | 110 | 160 | 190 | 200 | 230 |

| Breaking load, N, no less: CD | 10 | 13 | 18 | 22 | 32 | 46 | 60 | 70 | 100 | 130 | 150 | 180 | |

| 3. Elongation at break MD & CD, %, no more | EN ISO 9073.3 | 100 | 120 | ||||||||||

| 4. Steadiness to UV irradiation, %, no less after 500 hours (for UV stabilized materials) | ASTM D4355 | 45 | |||||||||||

| 5. Hydrophilic properties of material with hydrophilic additive. - liquid transmission time, s, max for marks: HG-WG | EN ISO 9073.8 | 2,2-2,8 | - | ||||||||||

| HG-WP (no more than) | 2,5 | - | |||||||||||

| HG-O | 3,0-4,0 | - | |||||||||||

| HG-ON, Л, С, М, Н (no more than) | 4,0 | 4,0 | 5,0 | 7,0 | 15,0 | 20,0 | 25,0 | 30,0 | 35,0 | 40,0 | 45,0 | 50,0 | |

| - wetback, g, max | WSP 80.10(05) | 5 | - | ||||||||||

| - liquid flow, g, max | EN ISO 9073.11 | 0,5 | - | ||||||||||

| 6. Air permeability at a 200 Pa, l/dm2 per min, not less | EN ISO 9073.15 | 3500 | 3000 | 2200 | 1900 | 1400 | 1100 | 600 | 500 | 250 | - | ||

Permissible deviations from norms of width should not exceed -0,+3 mm (60-300 mm), -0,+6 mm (301-700 mm), ±10mm (701-1000mm), ±15mm (1001-2000mm), ±20mm (2001-3200mm).

Permissible deviations from norms of the surface density should not exceed ± 5%.

Applications for Non-Woven Hydrobonded Fabric

This hydro bonded material has a very wide application in industry, construction, medicine, and in everyday life.

- MEDICAL CLOTHING AND ACCESSORIES - bathrobes for laboratory assistants and medical personnel and visitors of medical institutions, protective sheets for operating rooms and beds, disposable sheets, bed linen, surgical and pharmaceutical bathrobes and medical aprons, medical overalls, treatment trousers, jackets, medical workers' suits, medical personnel's headdresses, berets, hats, face masks and respirators, procedural and surgical shoes, armbands, napkins, slippers, bathrobes, sheets, disposable cloths for beauty, manicure and pedicure rooms, and more.

- SPECIAL PROTECTIVE WORK CLOTHES - aprons, bathrobes, suits, overalls and overalls for mechanics of auto engineering, laboratory assistants and attendants, personnel of hairdressing salons and cosmetic salons, employees of hothouses, employees of meat-packing plants, workers of the bakery industry, fishermen of fishing and sea vessels, workers of public catering, employees in the "clean" rooms of the electronic industry, etc.

- MATERIAL FOR SANITARY AND HYGIENIC PURPOSE - lady's bandages, diapers for children and the elderly, the top layer of diapers, etc.

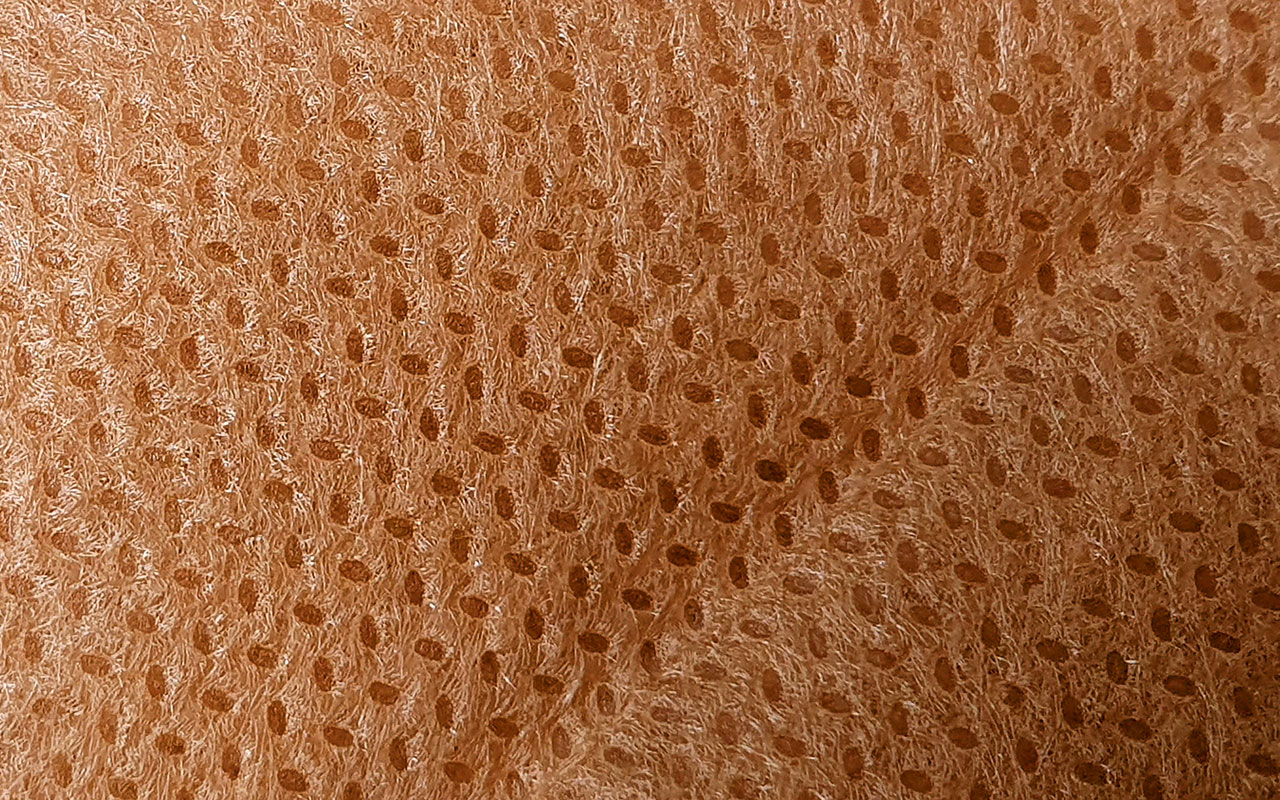

Non-Woven Thermobonded Material Photo