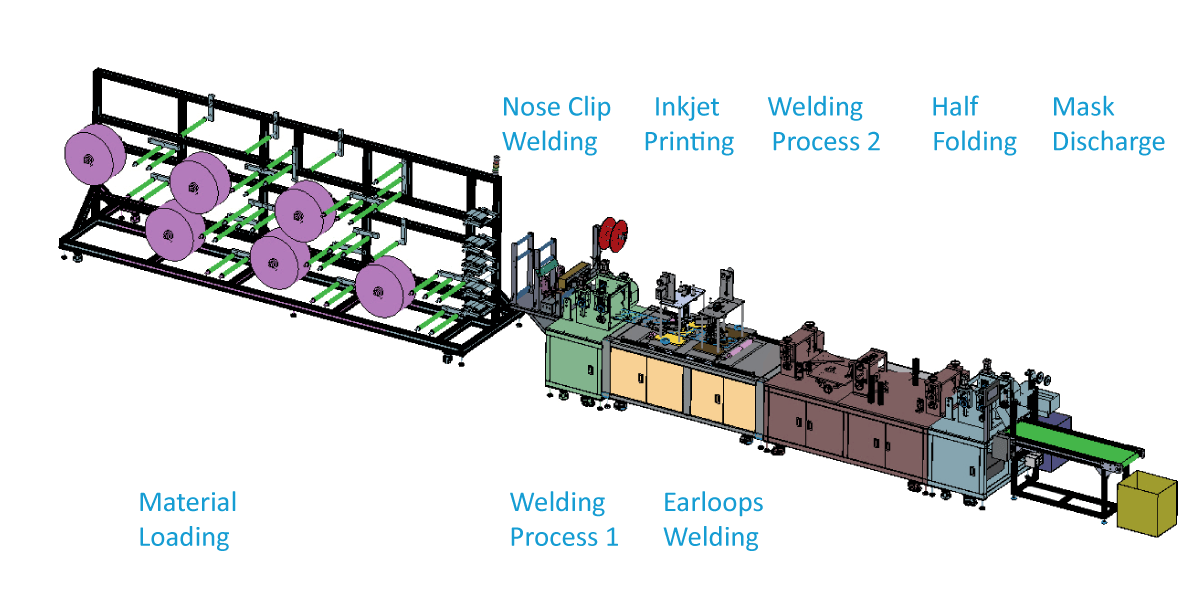

Automatic Folding N95 Respirator Mask Production Line

Folding masks production line application

The production line is designed to produce filtering facepiece respirators, also known as disposable respirators, flat folded face mask, meet the standard of N95, KN95, FFP2, etc. Suitable working with all kinds of non-woven fabric, spunbond, meltblown, hot air fabric, etc.

Samples of products

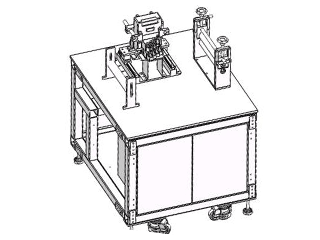

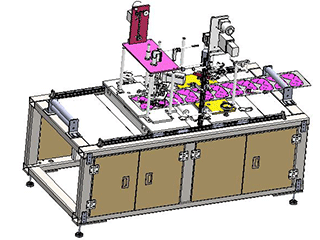

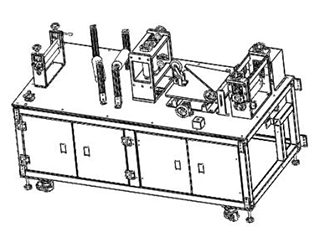

N95 Folding Masks Production Line Overview

Picture shown are for illustration purpose only. Actual product may vary due to product enhancement

Features & Advantages

Automatic Folded Respirator N95 FFP2 Mask Production Line has a number of features and advantages:

- Full automatic production line from raw material feeding, nose bridge attaching, pattern embossing, earloop fixing, mask shape sealing and cutting, mask folding, waste removing and discharge masks from the lines.

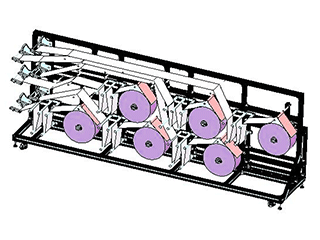

- Outer - filter - inner, up to 6 layers can be automated feed in alignment.

- Outline symmetrically weld and fold to make.

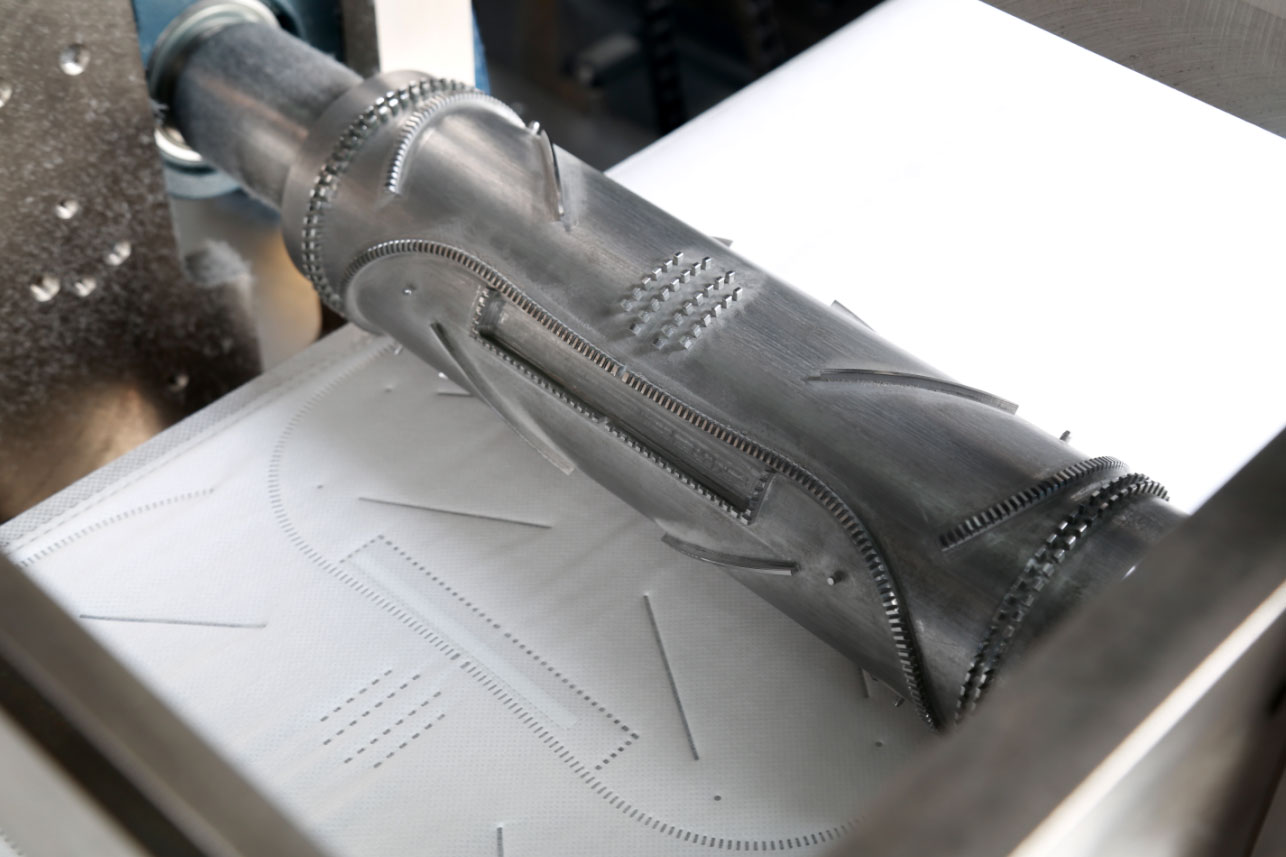

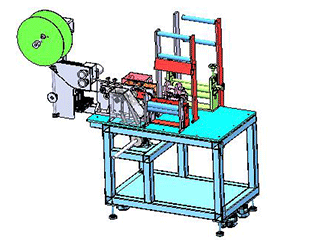

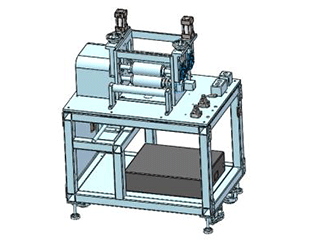

- Ultrasonic welding devices to form the pattern and cut edges continuously.

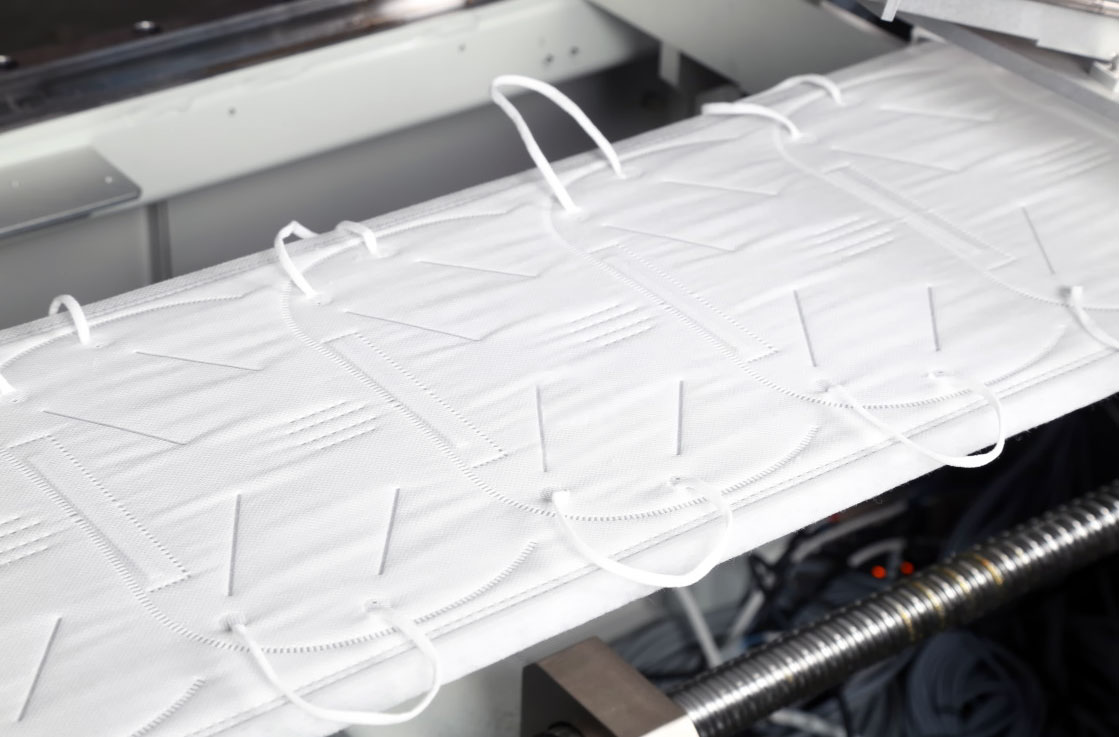

- Automatic sending elastic strips to earloop welding station.

- Automatic earloop ultrasonic welding and cutting.

- PLC control system, stable working system.

- Machine Design with easy and quick change of the pattern / shape mould, able to produce different type of mask design/shape/size.

- Automatically alarm and stop machine running when material run out.

- Optional Inner Nose bridge or Outer nose bridge devices.

- Optional Inkjet Printing and dring devices, flexible programmable for printing info & patterns.

Respirator folded N95 FFP2 Mask Production Line Technical Data

| Parameter | Value | |

|---|---|---|

| Mask Type | Foldable respirator mask | |

| Mask Size | Folded Size 160 mm × 105 mm (size can be changed by mould replacement) | |

| Line Speed | 50 - 60 pcs/min | |

| Mask Material | Hydrophilic non-woven fabric, melt-blown non-woven fabric, thermal bonding non-woven fabric | |

| Layer Quantity | 3 - 6 Layers | |

| Processing Mode | Ultrasonic welding + cutting | |

| Welding Patterns | Customized by sample | |

| Earloop Fix Type | Ultrasonic welding | |

| Operation Screen | 10 inches touch screen | |

| Air Source | 0.4≤ P ≤0.7 MPa, flow rate 300 L/min | |

| Ultrasonic Generator | 220V, 20kHz, 1.5 kW | |

| Power consumption | 10 kW | |

| Voltage | three-phase 380V / 50 / 60Hz | |

| Installation Area | 13000 mm × 2000 mm × 2100 mm | |

Flat Folding N95 Mask Production Line Optional Devices

Automatic Build-in Line Options

- Inner Nose clip device

- Outer Nose clip machine

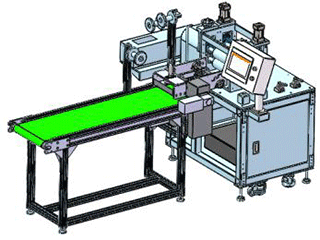

- Inkjet Printing & drying device

- Transfer printing device (70 × 70mm)

- Transfer printing device(120 × 100mm)

- Staple earloop machine

- Exhalation valve device

Manually Operate Options

- Manual Outer nose clip welding machine

- Manual Outer nose clip welding with sponge strip fixing machine

- Manual Staple earloop machine

- Manual Exhalation valve fixing machine

- Manual Inkjet printer

- Manual transfer printing machine

Folding Mask Making Process Stages

Material Loading up to 6 Layers

Nose Clip Cut & Feed

[*Inner / Outer Optional]

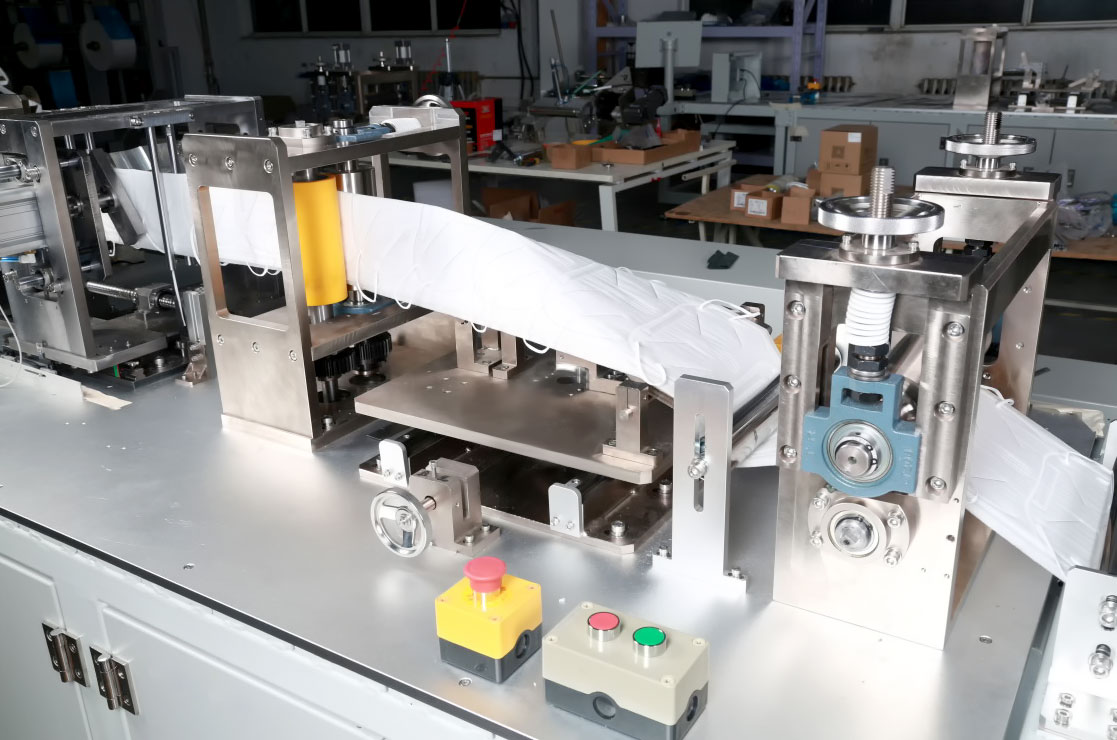

Welding Process 1: Mask Shape & Pattern

Inkjet Printing [Option]

Earloops Welding

Material Half Folding

Welding Process 2: Mask Sealing, Remove Waste, and Collect Finished Masks

[Option] Clip Welding

Manually operate type machine, for outer nose clip and sponge strip welding

[Option] Inner Nose Clip

Available with full automatic build-in Nose Clip production

[Option] Outer Nose Clip

Optional outer nose clip style with Automatic devices, or Manually Nose Clip operation.

Plastic type nose clip

Metal type nose clip

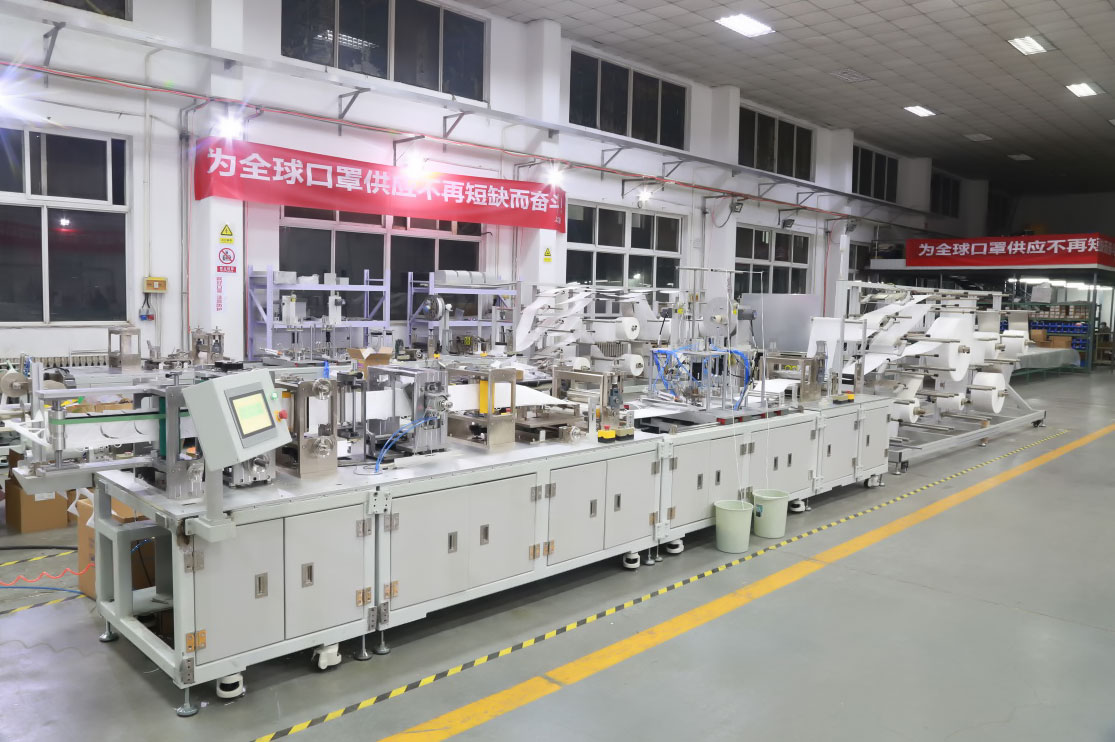

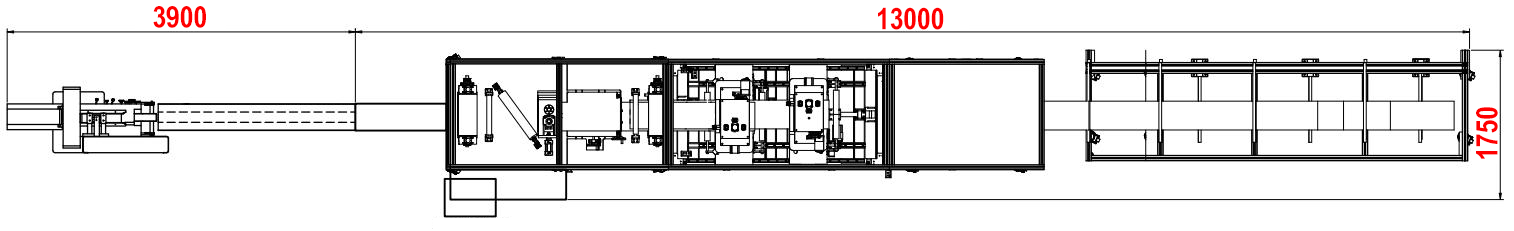

Layout of Automatic Production Line

Appearance of installed Production Line for Folding N95 Respirator Mask